Table of Contents

Size Reduction of Drugs

- It is the process of reducing drugs size in smaller particles, or fine powder.

- The term size reduction is applied to ways in which particles of solids are cut or broken into smaller pieces.

- Size reduction is necessary if the starting material is too coarse, and final product needs to be a fine powder.

Importance of size reduction

- To improve the stability of certain pharmaceutical dosage forms such as suspension the rate of sedimentation decrease to a large extent by reducing the particle size of the drug.

- To help in the process of separation of the solid from liquids by filtration by the rate of filtration depend upon the particle size.

- To increase the rate of absorption of a drugs the smaller particle size the greater is the rate of absorption.

- To increase the rate of solution is case of chemical substance become reduction of the particle size increases the surface area for the action of solvent.

- Due to size reduction, we are design the different type of drug dosages form (tablets, capsules, suspension and emulsion etc).

Factor affecting size reduction

- Hardness:- The hardness of the material affect the process of production it is easier brakes soft material to a small size then hard material. Due to the hardness of any material it affects the drug solubility and modification of any drug dosages form.

- Toughness:-The crude drugs of fibrous nature, it is not easily break down in smaller particle and shows the tough nature. In the toughness, materials fibrous are attached to each other in the layering form and affect the solubility of materials.

- Material structure:- Material structure is one of the major problem during the size reduction because special size and shape materials are easily break down by special machine or by special method.

- Moisture content: – The presence of moisture in the material influences a number of its properties such as hardness stickiness which in its turn effect the particle size reduction.

- The material having 5% moisture in case of drying grinding and 50% moisture in wet grinding does not create the problem.

- Stickiness:- Stickiness cause a lot of difficulty in size reduction this is due to the fact the material adhere to the grinding surface or sieve surface of the mill. Due to stickiness of material it affects the material weighing accuracy.

- Softening temperature:- Waxy substance (Stearic Acid, or drugs containing oil or fat) because softened during the size reduction process if a heat generated then the material not easily breakdown and sticks on the mill. If more the temperature generate in the machine, it affects the material stability and change their activity.

- Purity required:- Various mill are used for size reduction often cause the grinding surface to wear off and thus impurities come in the power if a high degree purity is required such mill must be avoided.

- Physiological effect:- Some drugs are very patent during their particle size reduction in a mill dust is produced which may have an effect on their operator in such cases the enclosed mill may be used avoid dust.

- Bulk density:- The output of the size reduction of material in a machine depends upon the bulk density of the substance.

- Ratio of feed size to product size:-To get a fine powder in a mill. It is required to fairly small feed size should be used hence it is necessary to carry out the size reduction process is several stage using different equipment.

- Example:- Preliminary crushing following by coarse powder and then fine grinding.

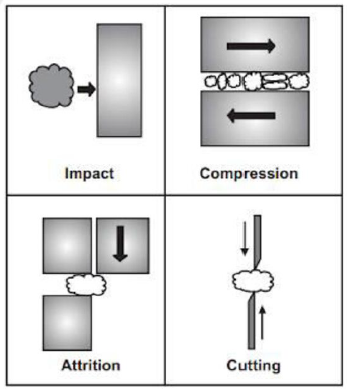

Methods of Size Reduction:

- Cutting

- Compression

- Impact

- Attrition

- Combined impact and attrition

- Cutting:- The material is cut on a small scale by means of a sharp blade knife, root cutter or other any sharp instruments on a large scale a cutter mill is used cutting of the drug is usually done to hasten the drying of drugs.

- Example: Cutter Mill, Shears, Scissors

- Compression:- In this method the material is crushed by the application of pressure on a small scale using mortar and pestle where as on a large scale roller mill is used.

- Example: Roller mill.

- Impact:-

Impact occurs when the material more or Less stationery and is hit by an object moving at high speed or when the moving particles strikes a stationary surface either case the material break into small pieces there is no apparatus which can be used on a small scale to effect side reduction by impact but on a large scale hammer mill and disintegrator are used.

- Example: Hammer Mill, Ball Mill.

- Attrition:-

- The action or process of gradually reducing the strength or effectiveness of someone or something through sustained attack or pressure. The attrition mill is a device for mechanically reducing solid particle size by intense agitation of a slurry of material being milled and coarse milling media.

- Pressure and shear force come together to reduce the size of the material when it comes between two moving platforms.

- Example: Roller Mill, Colloidal Mill

- Combined impact and attrition-

- It is based on the impact and attrition principle.

- Example- Ball mill.