Table of Contents

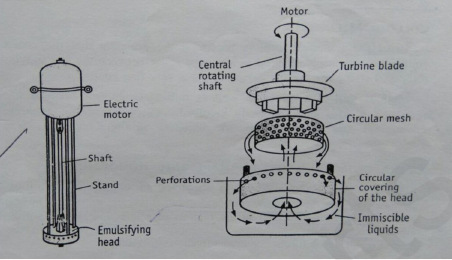

Silverson Mixer

Principle of Silverson Mixer

- Silverson mixer produces intense shearing forces and turbulence by the use of high speed rotors.

- This turbulence causes the liquids to pass through fine interstices formed by closely placed perforated metal sheets.

- Circulation of material take place through the head by the suction produced in the inlet at the bottom of the head.

- Circulation of the material ensures rapid breakdown of the dispersed liquid into smaller globules.

Construction of the Silverson Mixer

- It consists of long supporting columns connected to a motor which give support to the head. The central portions contain a shaft, one end of which is connected to the motor and the other end is connected to the head.

- The head carries turbine blades. The blades are surrounded by a mesh, which is further enclosed by a cover having openings.

Working of the Silverson Mixer

- The emulsifier head is placed in the vessels containing immiscible liquids in such a way that it should get completely dipped in the liquid.

- When the motor is started, the central rotating shaft rotates the head. This in tum rotates turbine blades at a very high speed.

- This creates a pressure difference; as a result liquids are sucked into the head from the center of the base and subjected to intense mixing action.

- The intake and expulsion of the mixture set up a pattern of circulation to ensure rapid breakdown of the bigger globules into smaller globules.

Uses/Applications of the Silverson Mixer

- Silverson mixer is used for the preparation of emulsions and creams of fine particle size.

Advantage of the Silverson Mixer

- Silverson mixer is available for thousand liter of mixing.

Disadvantage of the Silverson Mixer

- Occasional there is a chance of clogging of pores of the mesh.

- It requires high shear force

- It consumes high operating power.