Table of Contents

Freeze Dryer

Principle of Freeze Dryer

- In freeze dryer, water is removed from the frozen state by sublimation that is direct change of water from solid in vapour without conversion to a liquid phase.

- Heat is supplied which transfer as latent heat and ice sublimed directly into vapour state.

Eutectic point- The pressure and temperature at which the frozen solid vaporizes without conversion to a liquid is referred to s the eutectic point.

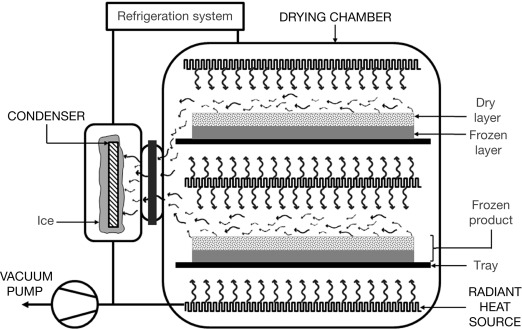

- Drying chamber in which trays are loaded.

- Heat supply in the form of radiation source, heating coils.

- Vapour condensing or adsorption system.

- Vacuum pump or steam ejector or both.

Working/process of freeze dryer

Working of freeze dryer include in many steps.

- Preparation and pretreatment.

- Prefreezing and solidifying water.

- Primary drying (sublimation of ice under vacuum).

- Secondary drying (removal of residual moisture under high vacuum).

- Packing.

- Preparation and pretreatment-

- The volume of solution introduced into the container is limited by its capacity. Satisfactory freeze drying beyond a certain limit of depth of liquid is not possible.

- Therefore pre-treatment is essential.

- The solution is pre-concentrated under normal vacuum tray drying. The final products become obtained becomes more porous.

- Prefreezing and solidifying water-

- Vials, ampoules or bottles in which the aqueous solution is packed are frozen in cold shelves about -50°C.

- During this stage cabinet is maintained at low temperature and atmospheric pressure.

- Primary drying-

- In this step, the material to be dried is spread as much large surface as possible for sublimation.

- The temperature and pressure should be below the triple point of water, that is 0.0098°C and 0.533 KPa for the sublimation, when water alone present.

- Primary stage removes easily removable moisture. During this stage about 98% to 99% water is removed.

- Secondary Drying-

- The temperature of the solid is raised to as 50 to 60° C but vacuum is lowered below that is used in primary drying.

- The rate of drying is very low and it takes about 10 to 20 hours.

- Packing-

- After vacuum is replaced by inert gas, the bottles and vials are closed.

Uses/Applications of freeze dryer

- It is commonly used in the production of dosages forms as injections, solutions, and suspensions.

Advantage of freeze dryer

- Moisture level can be kept as low as possible without decomposition.

- Thermolabile materials can be dried

- Sterility can be maintained.

Disadvantage of freeze dryer

- Equipment costs very high.

- The period of drying is very long.