Table of Contents

CYCLONE SEPARATOR

Principal of Cyclone Separator

- In cyclone separator, the centrifugal force is used to separate solids from fluids.

- The separation depends not only on the particle size but also on density of particles.

- Hence depending on the fluid velocity, the cyclone separator can be used to separate all types of particles or to remove only coarse particles and allow fine particles to be carried through with the fluid.

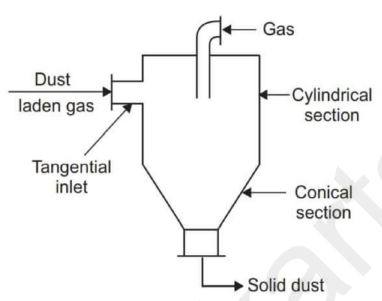

Construction of Cyclone Separator

- It consists of a tapering cylindrical vessel which consisting of a top vertical section and lower conical/tapering section terminating in an apex opening – a short vertical cylinder which is closed by a flat plate on top and by a conical bottom.

- It is provided with a tangential feed inlet nozzle in the cylindrical section near the top and an outlet for the gas, centrally on the top.

- The outlet is provided with a downward extending pipe that extends inward into the cylindrical action to prevent the gas short-circuiting directly from the inlet to the outlet and for cutting the vortex.

Working of Cyclone Separator

- The suspension of a solid in gas (usually air) is introduced tangentially at a very high velocity, so that rotary movement takes place within the vessel.

- The fluid is removed from a central outlet at the top. The rotatory flows within the cyclone separator generate the centrifugal force on the particle.

- The solids are thrown out to the walls; thereafter it falls to the conical base and discharged out through solids outlet.

| Advantages | Disadvantages |

|---|---|

| Low capital cost. | High operating costs (due to pressure drop). |

| Ability to operate at high temperatures. | Low efficiencies (particularly for small particles). |

| Can handle liquid mists or dry materials. | Unable to process “sticky” materials. |

Uses of Cyclone Separator

- Cyclone separators are used to separate the suspension of a solid in a gas (air).

- It can be used with liquid suspensions of solids.