Table of Contents

Sintered Glass Filter

Principle of Sintered Glass Filter

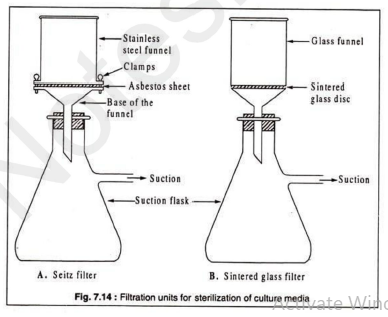

It is works on the principle of Reducing pressure. During the filtration high pressure exerts on the sintered glass disc and lower pressure exert on the base of funnel. Due to pressure difference filtration is performing.

Construction of Sintered Glass Filter

- It consists of the glass funnel and sintered glass disc.

- These filters have as a filtering medium a flat or convex plate of Jenna glass powdered and shifted to produce granules of uniform size that are moulded together.

- The variation in porosity depending on size of granules used in the plate.

- A vacuum attachment is necessary to facilitate the passage of liquid through the filter plate.

Working of Sintered glass filter

The sintered glass filters are available in different pore size. Hence the funnel with a sintered filter is numbered according to the pore size.

- The filtration is carried out under reduced pressure. These funnel are used for bacterial filtration.

Uses/Applications of Sintered glass filter

- Sintered filters are also available in stainless steel which has a greater mechanical strength.

- However these are very much liable to attack by the solutions passing through them.

Advantages of Sintered glass filter

- It is easy to clean and labor requirement is very low.

- It shows low absorption properties.

Disadvantage of Sintered glass filter

- It is fragile in nature so its handling is very tough task.

- It is very expensive and time consuming.