Table of Contents

Double cone Blender

Principal of Double cone blender:

It is an efficient design for mixing of powder of different densities. It is usually charged and discharged through the same port. These are used mostly for small amounts of powders.

The rate of rotation should be optimum depending on the size and shape of the tumbler, nature of materials to be mixed. Commonly the range is 30 to 100 R.P.M.

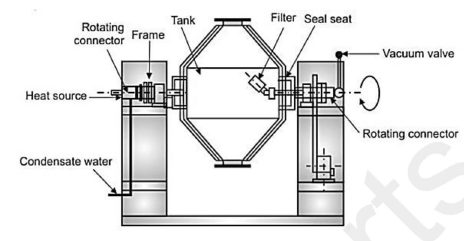

Construction of Double cone blender:

- The conical shape at both the end enable uniform mixing and easy discharge.

- The cone is statically balanced which protects the gear box and motor from any excessive load.

- Powder is loaded into the cone through a wide opening and discharged through a butterfly or a slide valve.

- Depending upon the characteristic of the products, paddle type baffles can be provided.

Working of Double cone blender:

- The material is loaded approximately 50% to 60% of its total volume. As the blender rotates, the material undergoes tumbling motion.

- This motion dividing and recombination continuously yields ordered mixing by mechanical means. Blender speed is the key for mixing efficiency.

- At high speed, more dusting or segregation of fines is possible, while at low speeds, not enough shears may be applied.

Uses/Applications of Double cone blender

- It is an efficient and versatile machine for mixing of dry powders and granules homogeneously.

Advantage of Double cone blender

- It is suitable for fragile granules because of minimum attrition.

- Easy to clean, load and unload.

- They handle large capacities.

- This equipment requires minimum maintenance.

Disadvantages of Double cone blender

- Need high head space for installation.

- It is not suitable for fine particulate system or ingredients of large differences in the particle size distribution because not enough shears is applied.