Table of Contents

Hammer Mill

Principal of Hammer Mill

It work on the principle of impact.

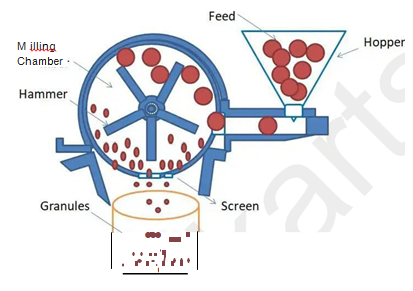

Construction of Hammer Mill

It consists of metal causing inclosing a control shaft to which four or more swinging hammer are attached the lower part of the mill, consists of a screen through which material can pass in a suitable receiver when the discrete of size reduction is reached.

Working of Hammer Mill

- The material is put into the hopper.

- Which is connected with the drum the material is powered to the desire size due to fast rotation of hammer and is called under the screen this mill has the advantage of continuous operation because the chance of jamming is less as the hammer are not fixed the material can product coursed to moderately fine powder.

- Due to the high speed of operation heat is generated which may affect themselves drugs are material more ever high speed of operation.

Advantages of Hammer Mill

- It is used for production of intermediate grade of powder.

- It can be operated continuously.

- It is effecting in function and can grind different type of material.

Disadvantages of Hammer Mill

- Due to high speed heat is generated.

- It is not suitable for heat sensitive material.